Power Supply Tests

Testing improves more than a power supply’s reliability. Benchmark testing ensures the power module satisfies its intended use’s power and quality requirements.

Power supply issues like noise and stability may not need total power outages but may degrade the power module over time.

Power Supply Testing Procedures Are Detailed Below

Verifying Output Voltage Accuracy: Paralleling the power supply and measurement device is common for voltage accuracy. After connecting the oscilloscope probe’s ground wire to the power supply’s ground, the probe is used to connect the voltage being examined to the power supply. Check the board’s voltage accuracy with and without a load.

First, we adjust output at full load and standard input voltage. Next, we record the specification’s nominal output voltage (Vnom) and output voltage (Vout). Finally, output voltage accuracy = (Vout – Vnom) / Vnom * 100%.

Ripple/Noise Analysis: AC ripple and noise reduce DC output precision. Ripple and noise are commonly measured using peak-to-peak (MVP-p).

They set the oscilloscope bandwidth to 20MHz before ripple, and noise testing filters out high-frequency noise. Ripple and noise are measured using a parallel cable, twisted-pair cable, or contact measurement.

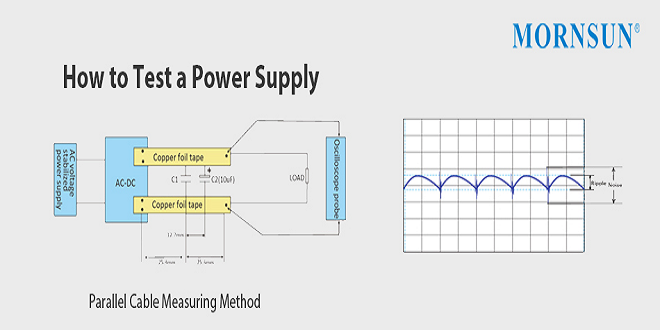

Method of Parallel Cable Measurement

Two copper foil tape layers cover the tested AC/DC power source. An exotic capacitor and a 1uF high-frequency ceramic capacitor are paralleled on copper foil tape. Two parallel tapes should be 2.5 mm apart and lose less than 2% of the output voltage. Connect the oscilloscope probe to the copper foil tape ends to record the test value.

Twisted Pair Cable Measurement

First, we connect the Vo and OV of the switching power supply under test using a 30cm, 20AWG twisted-pair wire. Next, we link a false load of resistance between Vo and OV. Finally, we connect a 10uF electrolytic capacitor to the twisted pair’s end. Finally, connect the measurement point to the Vo and the grounding ring.

Contact-Based Measuring

If high-frequency noise isn’t filtered out, the oscilloscope’s ground clamp might take up much of it, affecting results.

We can connect the AC/DC Under Test’s Vo and OV ends to the oscilloscope’s grounding ring without an adaptor. Results show that ripple and noise depend on the circuit and external components.

Conclusion

Benchmark testing is essential for a power supply to work properly under various input and load conditions. For example, engineers may prevent expensive design adjustments or board revisions during final manufacturing by properly evaluating the power supply. Contact us for a free sample of ac to dc converters or inquiries about Mornsun‘s power supply options.